- Bentley Motors unveils Batur Convertible at an exclusive launch event in Dubai

- Handcrafted by Mulliner, Bentley’s bespoke division, it is the third coachbuilt Bentley of the modern era

- An evolution of Bentley’s DNA, capturing the essence of open-air Grand Touring in a progressive design born from Batur

- Each example is one of the last ever Bentleys to use the iconic 750PS W12 engine

- Follows the two-door Bacalar barchetta and Batur coupe

[source: Bentley]

Dubai, UAE – The Batur Convertible, the third coachbuilt Bentley of the modern era, has made its global debut at an exclusive event held in Bab Al Shams in Dubai, UAE.

With only 16 individually numbered cars being produced, the Batur Convertible is a true collector’s piece. Each will feature the most potent iteration of Bentley’s iconic W12 engine, a 750 PS, hand-assembled 6.0-litre twin-turbocharged masterpiece set to end production this summer, making this one of the last Bentleys to ever house this legendary powertrain. Beyond its extraordinary performance, the Batur Convertible offers limitless personalisation, with every detail tailored to reflect the vision and individuality of its owner.

Design details

The exterior of the Batur Convertible Engineering Car, currently in Dubai, is another demonstration of the art of the possible with the Mulliner Bespoke Studio. It is a showcase of dynamic colour transitions and high-performance materials, brought to life through its Midnight Emerald exterior paint and High Gloss Carbon Fibre finishes. At the front, the grille stands out with a bold Satin Dark Titanium finish throughout, with the exception of the grille matrix, where a Gloss Mandarin to Gloss Beluga fade creates a striking visual transition.

At the heart of this bold exterior is the distinctive Batur Racing Stripe, finished in Gloss Porpoise and flanked with Gloss Mandarin outer stripes, both hide-matched to the interior leather, creating a seamless visual connection between the exterior and the cabin.

The cabin echoes the exterior, with Cumbrian Green and Porpoises leather being accented with Mandarin stitching and piping, complemented with machined titanium Organ Stops and Bullseye vents. The veneer is Mulliner’s exquisite “guitar fade”, where a transition of colour and texture spans the width of the cabin, from gloss Beluga to high gloss carbon fibre, and back to gloss Beluga, and finished with the unique laser-etched audio signature of this W12 engine.

Bespoke two-seat grand touring

Bentley has a rich history of open-cockpit cars, from the very first Bentley of 1919, through the company’s foundation years in the 1920s, to the most recent – the Bacalar.

The architecture of the Batur Convertible has allowed Mulliner’s designers to seize the opportunity to create a theme that not only blends the design of the Bacalar and Batur but includes the versatility of a convertible. The designers also chose to highlight the two-seater character with a ‘wraparound’ cockpit inspired by the design of the Bacalar.

Personal and uniquely commissioned

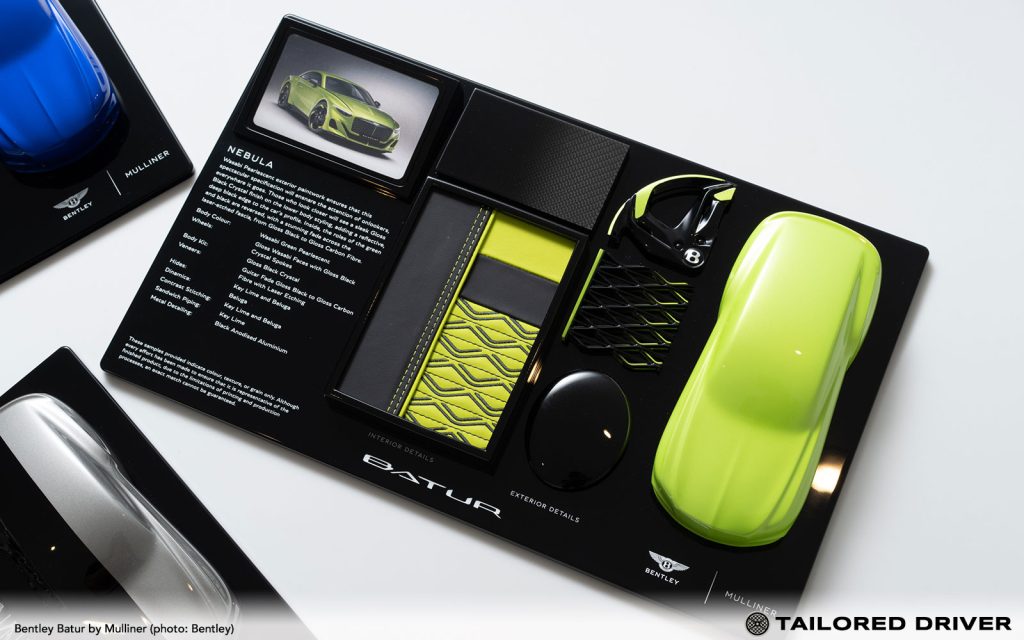

The Mulliner Bespoke Studio will co-create every Batur Convertible with each client, utilising our exclusive in-house commissioning software. It adopts a unique ‘off menu’ approach to commissioning that allows any part of the car to be customised in colour and surface finish, bringing each vision to life.

Endless samples of unique materials bring texture and feel to the process, with the resulting commissions being truly individual and created by the client, limited only by their imagination.

Paint choice is infinite, starting with the full Mulliner colour palette and travelling beyond into fully bespoke paint and even hand-painted elements. The exterior brightware can be any mix of light and dark, satin or gloss, or even titanium. Another subtle option available is a graduated contrast colour to the front grille, allowing for a vibrant ombre effect.

In the cabin, the highly exclusive option of 3D printed rose gold includes key driver touch points, such as the Bentley Drive Mode Selector, encircling the start/stop button and used to change chassis modes. The centrepiece of an exquisite cabin, the dial complements the design of the front grille. Rose gold can also be applied to Bentley’s iconic Organ Stop vent controls in the dashboard, as well as on the steering wheel itself.

Bentley Mulliner has collaborated with expert goldsmiths based in the historic Jewellery Quarter of Birmingham, England, where jewellery has been made for centuries, to craft these unique parts. This special collaboration highlights Bentley’s ability to combine new, advanced manufacturing technologies with more traditional materials and finishing techniques.

Exclusive and powerful

Each Batur Convertible will be handcrafted over the course of several months in Mulliner’s workshop at Bentley’s carbon-neutral factory in Crewe, England. The Batur features the most powerful version of Bentley’s iconic W12, a 750 PS, hand-assembled 6.0-litre twin-turbocharged engine that has metaphorically and literally powered Bentley’s success for the last two decades.

For the W12 powertrain that the Batur Convertible shares with its coupe counterpart, a revised intake system, upgraded turbochargers, new intercoolers, and extensive recalibration enable 750 PS and 1,000 Nm of torque, to deliver exceptional performance for this pinnacle grand tourer. This development of the engine is in celebration of its achievements over 20 years, over which it has been developed to produce nearly 40% more power while improving fuel economy by 25%.