- Created by hand in the Mulliner workshops over eight months

- Culmination of a boyhood dream, inspired by a child’s toy

- Unique specification has personal significance to owner and family

- Special green ‘Embelo’ finish named for their three daughters

- Owner’s garage includes Continuation Series Blower, a first generation Continental GT, rare Continental GT3R, Supersports and Bentayga

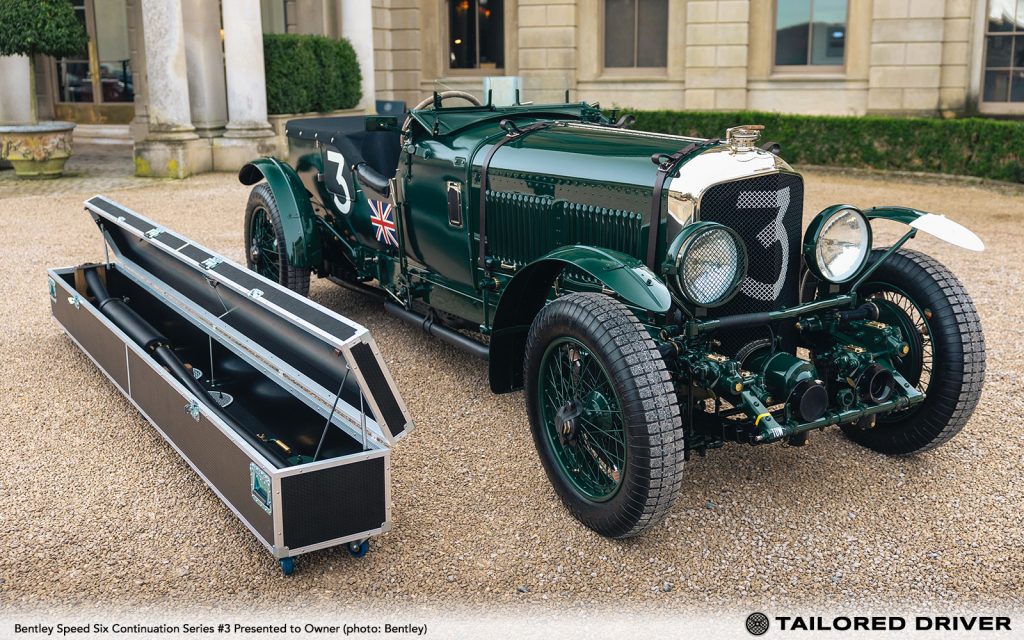

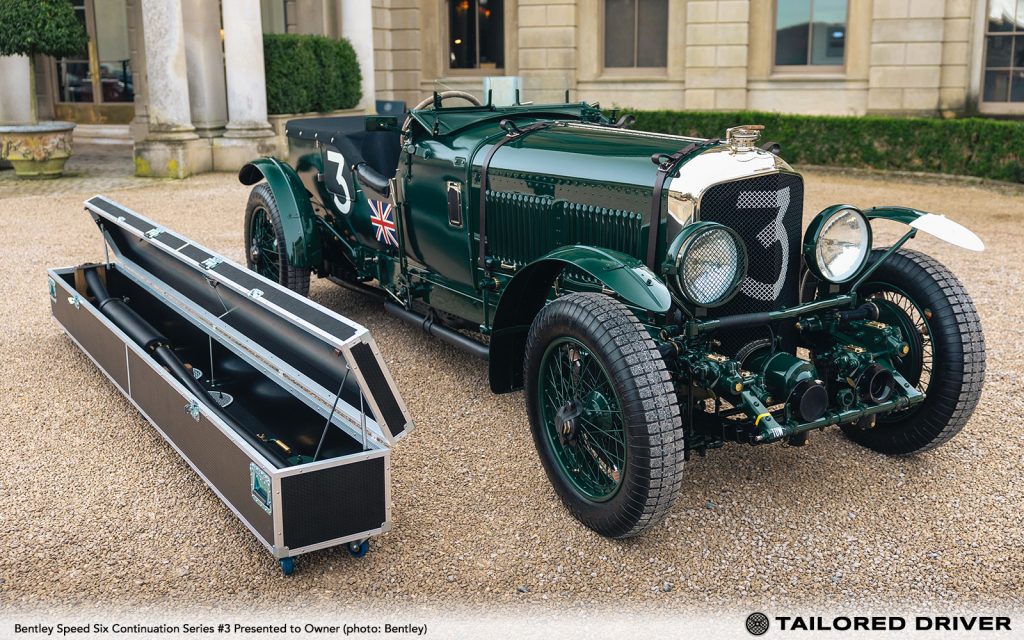

- Handover took place at Cliveden House, Berkshire.

[source: Bentley]

Crewe, England – Many a Bentley owner’s love of the marque begins in childhood, and the owner of the third of twelve Speed Six Continuation Series is no exception. In his case, it was a ‘Models of Yesteryear’ scale model Blower Bentley, given to him by his uncle, that sparked a lifelong fascination with the pre-war Bentley racing cars.

The owner and his wife enjoy a stable of Crewe-built Bentleys, including a first-generation Continental GT, a motorsports-inspired Continental GT3R, second-generation Continental Supersports and First Edition Bentayga. Pride of place however goes to his Continuation Series ‘Blower’ 4½ Litre Supercharged and the latest addition, a Continuation Series Speed Six. Not only has he kept that cherished scale model ‘Blower’ to this day, but it also provided the visual inspiration for his two Bentley Continuation Series cars.

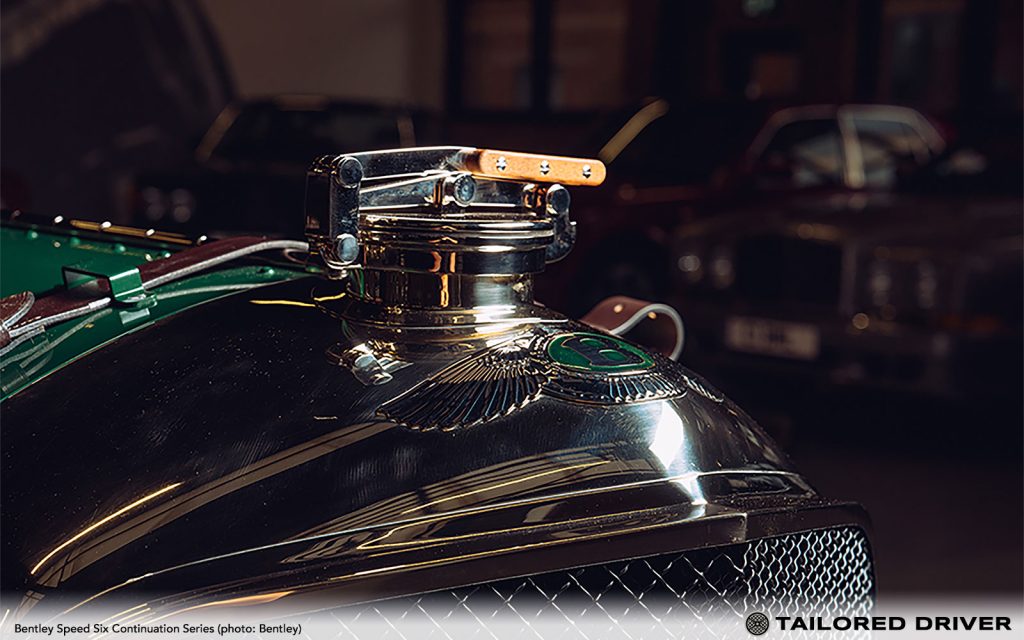

At the workshops of Mulliner Classic, realising a customer’s dreams is both their calling and their pride. Continuation Speed Six #3 (of 12) is a case in point; created with meticulous attention to detail to be identical in every respect to the original 1930s works racer, it also features several personal touches in its specification that make it truly individual, from the one-off paint finish to the racing number 3 that it carries on its flank and radiator.

Personal memories and family associations

Both the Continuation Series Speed Six and the Continuation Series Blower are the third of twelve in their series, and the Speed Six also carries the racing number 3. The number that has fond associations for the owner, who played rugby to semi-pro standard as a tighthead prop, wearing the number 3 jersey, for many years.

Both the Blower and the Speed Six are finished in the same specially blended shade of green, chosen after careful consideration to be mid-way between the light green of the owner’s scale model and traditional British Racing Green. The shade was christened ‘Embelo Green’, taking the first letters of the couple’s three daughters. Like the owner’s scale model Bentley, his Speed Six Continuation Series’ interior is upholstered in red, though the couple chose a more muted shade than that of the toy.

As with all this owner’s Bentleys, the Speed Six will be regularly and enthusiastically driven. Accordingly, another special request was for the Mulliner team to provide two exhaust systems with the Speed Six: one unsilenced as the original Speed Six specification, and the other with a silencer for circuits where noise restrictions are required. Bentley Mulliner engineering developed this silencer specifically for the Speed Six Continuation series. Finishing touches include a white patch on the leading edge of the nearside front fender for easier identification when coming into the pits and a hand-painted Union Flag on the driver’s side of the car.

A hands-on experience

Commissioning a Continuation Series Bentley is a highly personal process and, like many Mulliner Classic customers, the owner of the #3 Speed Six became a familiar figure in the Crewe workshops. A highly capable craftsman in his own right, he even spent a day working as part of the Mulliner team to fit the period-correct Rexine fabric of his Blower’s Weymann-style bodywork. While work commitments meant he was unable to do the same for his Speed Six, he fully intends to use it as W.O. Bentley intended – fast, reliable and capable of impressive performance.

The legendary Speed Six

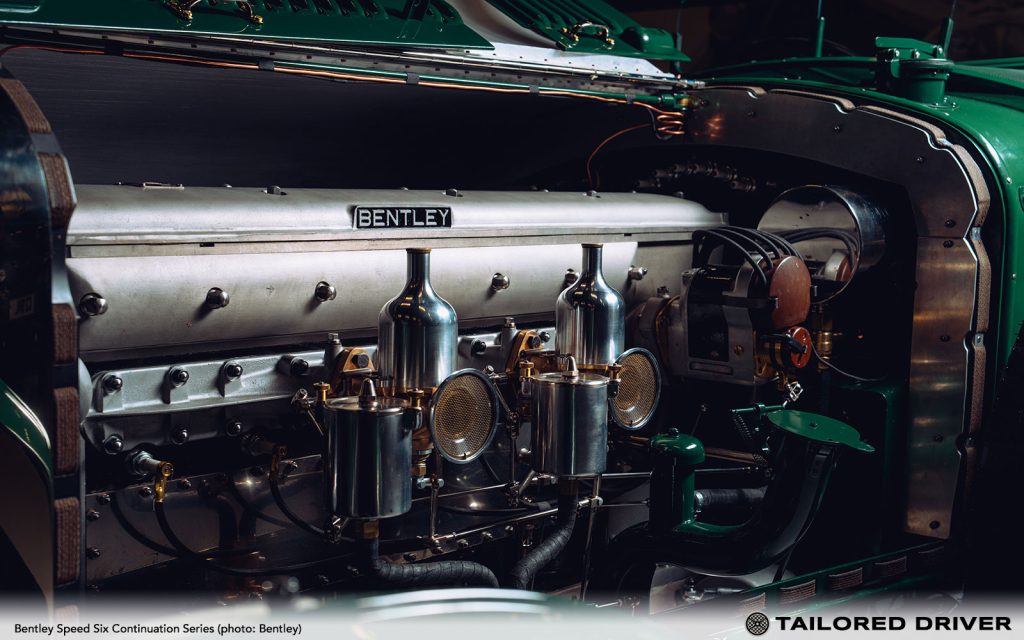

The Speed Six was introduced in 1928 as a more sporting version of the Bentley 6½ Litre. The engine was modified to liberate more power, with twin SU carburettors, a higher compression ratio and a high-performance camshaft.

182 Speed Six models were built between 1928 and 1930. Two wins at the Le Mans 24 Hour race, in 1929 and 1930, cemented the Speed Six’s pre-eminent place in Bentley racing history.

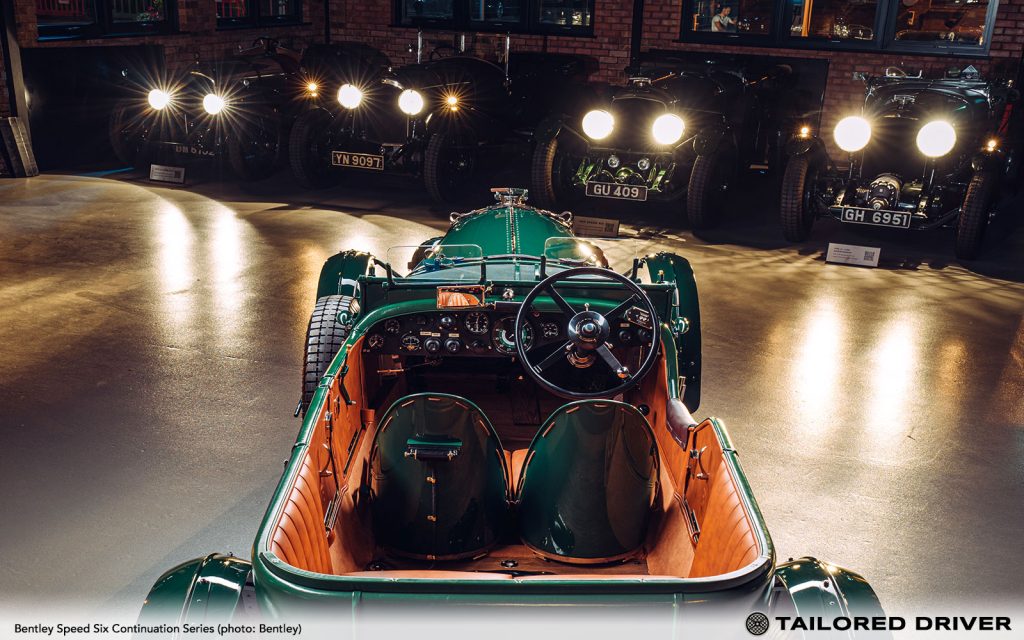

For the Continuation Series Speed Six, Mulliner Classic took two original Speed Sixes as its template: the company’s own Speed Six, GU409, and ‘Old Number 3’, a works Speed Six driven in the 1930 Le Mans 24 Hour race by Sammy Davis and Clive Dunfee. The latter was generously loaned by its owner and gave the Mulliner team invaluable data on dimensions, materials, and components. The Mulliner Classic team is also indebted to the W.O. Bentley Memorial Foundation, which provided 80% of the original drawings and notes used by the team.

About Bentley Motors

Bentley Motors is the most sought-after luxury car brand in the world. The company’s headquarters in Crewe is home to all of its operations including design, R&D, engineering, Mulliner and production of the company’s five model lines, Continental GT, Continental GT Convertible, Flying Spur, Bentayga and Bentayga EWB. The combination of fine craftsmanship, using skills that have been handed down through generations, alongside engineering expertise and cutting-edge technology is unique to UK luxury car brands such as Bentley. It is also an example of high-value British manufacturing at its best. Bentley employs around 4,000 people at Crewe.